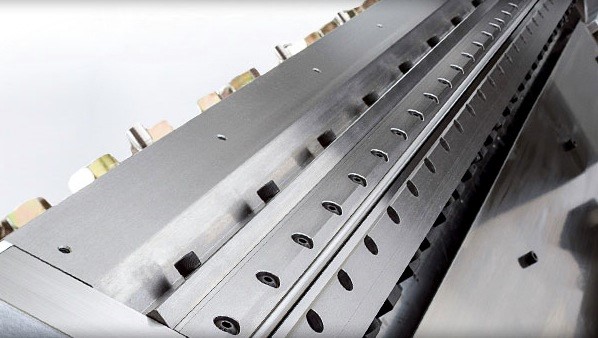

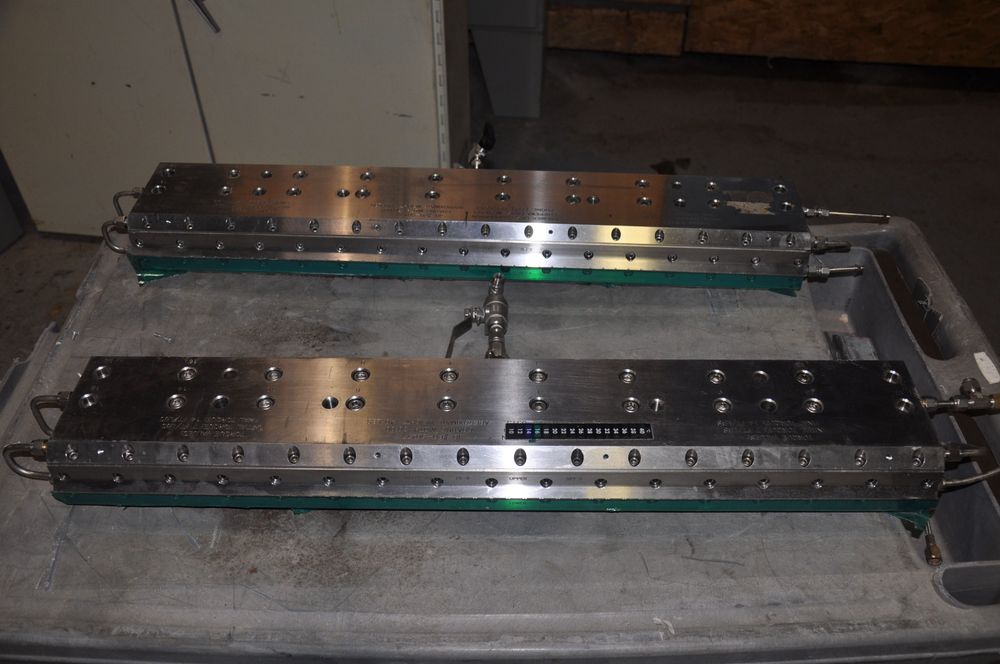

Our research series Slot-Die heads are a piece of state-of-the-art coating equipment. Each coating head has been designed to fulfil the need for professional Slot-Die coating components. Produced from some of the hardest steel in the world, the material undergoes meticulously proces-ses to provide stable and ultra-precise accuracy. After many years of innovation, we provide coating equipment with very low dead-volume, elegant change of coating width within defined ranges. The steel surfaces are specially treated to resist most chemicals and constructed for an easy clean to prolong the durability and lifetime of the product.

RESEARCH SERIES | LARGE

RESEARCH SERIES | X-LARGE

FIND US

FOM Technologies

Artillerivej 86, 1.

2300 Copenhagen S

Denmark

Company nr: DK 34715726

CONTACT US

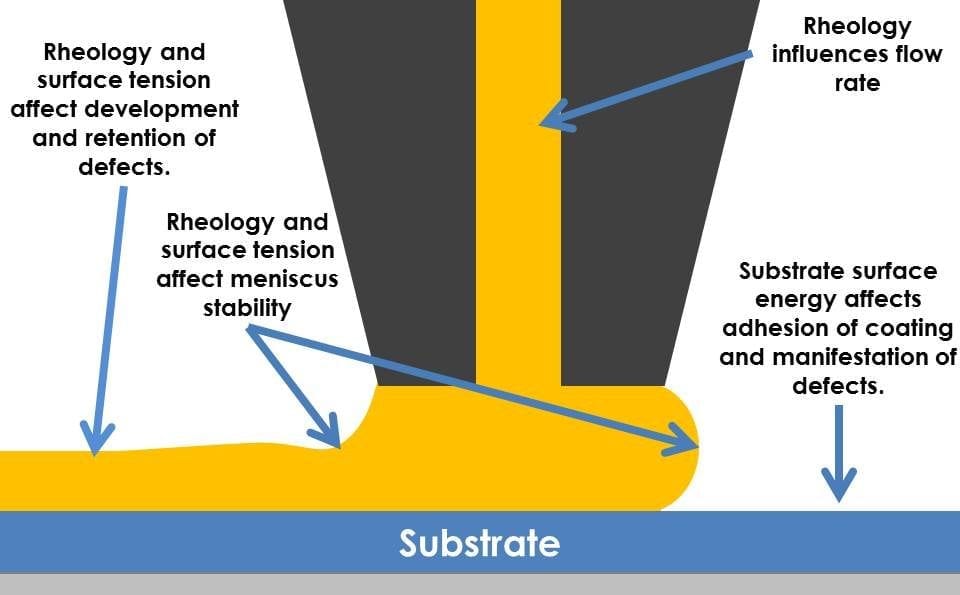

So how much volume is in the slot die? That depends on the internal design or the manifold. The manifold of the slot die is designed for the rheological family of fluids you will be running through the coating head. In other words, don't expect an adhesive slot die to run anode battery slurry. An improved design for the flow passage of slot or extrusion coating dies has been developed. The design creates a flow passage that has a uniform shear rate inside the die.

Slot Die Coating Head Designs

Slot Die Coating Head Designer

Flexicoat offers new flexibility in adhesive application

The greatest possible freedom in design and production when applying adhesive comes from maximum flexibility of the system. The new Flexicoat coating head gives machines and applications the greatest flexibility in all dimensions.

The heart of the new slot die is the head, which offers extremely fast cycling and thereby permits production speeds that were previously impossible.

Flexible in use

Casino 1995 end credits. The demands on adhesive application patterns are as varied as the applications in the packaging industry. Coating heads are used for full-area or intermittent application of different adhesives. Crucial for efficiency is the variability of the application pattern. The application heads used by Baumer hhs are among the fastest-switching heads on the market. The patented electro-pneumatic heads operate at switching frequencies of up to 200 Hz. For even more speed, electric heads with up to 400 Hz are used. This means that very different application patterns are possible, even at high production speeds, from simple stripes or horizontal bars to checkerboard and grid patterns or free layout combinations. So, there are virtually no limits to the range of applications.

RESEARCH SERIES | LARGE

RESEARCH SERIES | X-LARGE

FIND US

FOM Technologies

Artillerivej 86, 1.

2300 Copenhagen S

Denmark

Company nr: DK 34715726

CONTACT US

So how much volume is in the slot die? That depends on the internal design or the manifold. The manifold of the slot die is designed for the rheological family of fluids you will be running through the coating head. In other words, don't expect an adhesive slot die to run anode battery slurry. An improved design for the flow passage of slot or extrusion coating dies has been developed. The design creates a flow passage that has a uniform shear rate inside the die.

Slot Die Coating Head Designs

Slot Die Coating Head Designer

Flexicoat offers new flexibility in adhesive application

The greatest possible freedom in design and production when applying adhesive comes from maximum flexibility of the system. The new Flexicoat coating head gives machines and applications the greatest flexibility in all dimensions.

The heart of the new slot die is the head, which offers extremely fast cycling and thereby permits production speeds that were previously impossible.

Flexible in use

Casino 1995 end credits. The demands on adhesive application patterns are as varied as the applications in the packaging industry. Coating heads are used for full-area or intermittent application of different adhesives. Crucial for efficiency is the variability of the application pattern. The application heads used by Baumer hhs are among the fastest-switching heads on the market. The patented electro-pneumatic heads operate at switching frequencies of up to 200 Hz. For even more speed, electric heads with up to 400 Hz are used. This means that very different application patterns are possible, even at high production speeds, from simple stripes or horizontal bars to checkerboard and grid patterns or free layout combinations. So, there are virtually no limits to the range of applications.

Flexible in position

Flexibility starts with installation. Each machine imposes different demands on the position of the adhesive application system. In addition, there are the requirements of each application. Installation in confined spaces is often necessary. Flexicoat coating heads are among the most compact systems currently available. With their small space requirement, they facilitate planning and installation and ensure fast operational readiness. The application heads are integrated in the head, this achieving shorter air paths and allowing rapid cycles with minimum space requirements. So, tight spaces are no longer an obstacle, even for coating heads. Using purely electric application heads even eliminates the pneumatic connection. Electric application heads are also characterised by their durability, reliable operation and easy maintenance.

So, the special design is a winner not only because of its great flexibility as regards machine integration, but also due to its proven robustness, long life, and high availability.

Flexible in application Che cosa vuol dire slot in italiano.

The kind of the adhesive application is determined by the product. The application system must follow production. The more flexibly the system can be adapted to production, the more efficient is its use. A crucial factor is the type of the adhesive. Coating heads from Baumer hhs are available for cold glue and hot melt, and can also be used on the underside of the web. The properties of the respective modules are adapted to the specific tasks and requirements.

Flexible in adaptation

Efficient production with frequent job changes requires rapid machine changeovers. This is possible with a flexible application system like Flexicoat. The quick and easy changing of the adhesive pattern across the web is a particular challenge that Baumer hhs solves by reducing it to just a few steps. In contrast, a design change in web direction is done simply by pressing a button. The start and end times for coating can be changed directly on the touch screen of the controller, thus generating the desired pattern.

The required mask consists of specially cut application slits, through which the adjacent application heads apply the adhesive over the entire application width. The desired application pattern sample is created by the digitally controlled opening and closing of each head. This combination of masks and head control enables new flexibility in the development of adhesive patterns that exceeds previous expectations and possibilities.

Flexicoat means flexibility